Variable Compression Ratio Engine (VCR)

Fuel economy has an ever rising priority in combustion engine development. Further optimisation of conventional approaches will give only minor improvements, thus only new technologies will enable significant progress in the future. The variable compression ratio has the highest potential of all single technological steps and offers a great synergetic potential to other technologies such as variable valve trains and roller bearing crank drive.

Doğu Motor has a long time experience in developing engines with eccentric crank main bearings for a variable compression ratio while this system has been continuously improved. The latest versions offer a neutral engine length and friction compared to conventional crank drives.  The full thermodynamic potential can only be used with a wide range of epsilon variation between about 9 and 17, which can easily be achieved with the Doğu Motor system but only with few other systems. The system has been successfully applied and tested to Otto and Diesel engines.

The full thermodynamic potential can only be used with a wide range of epsilon variation between about 9 and 17, which can easily be achieved with the Doğu Motor system but only with few other systems. The system has been successfully applied and tested to Otto and Diesel engines.

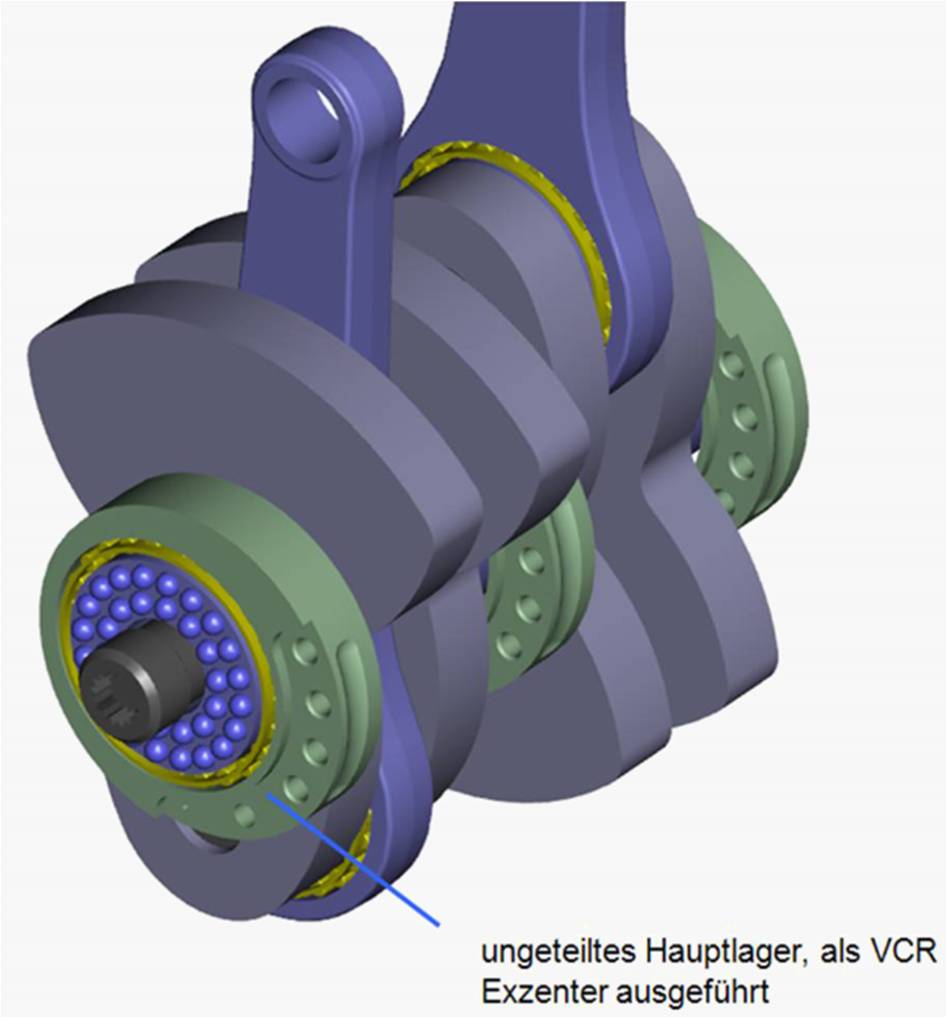

Besides thermodynamic improvements, even mechanical losses can be reduced in the combination with a roller bearing crank drive. The variable compression ratio can be used to reduce the bearing loads and offers excellent mechanical conditions for the application of roller bearings. The floating bearing of the excenter within the crank case is damping the roller bearing noises and prevents any kind of pre deformation by heat expansion or screw forces. Doğu Motor developed a simple but stable parting of crank shafts which eases the use of undivided roller bearing excenters.

Besides thermodynamic improvements, even mechanical losses can be reduced in the combination with a roller bearing crank drive. The variable compression ratio can be used to reduce the bearing loads and offers excellent mechanical conditions for the application of roller bearings. The floating bearing of the excenter within the crank case is damping the roller bearing noises and prevents any kind of pre deformation by heat expansion or screw forces. Doğu Motor developed a simple but stable parting of crank shafts which eases the use of undivided roller bearing excenters.

The useful combination of variable compression ratio, variable intake timings, supercharged downsized engines and roller bearings will give efficiency benefits of about 20% even to modern downsized engines.