Gasoline engines:

A fully variable valve train enables a great decrease of throttle losses by free choice for inlet opening and closing timings. Furthermore the combination with a cam phaser will increase torque and power over the entire rpm range. On boosted engines, it is possible to reduce the air mass in the cylinder not by a waste gate but by shortening the valve timings. By doing so, the temperatures in the cylinder can by lowered, which results to reduced tendencies for knocking.

A fully variable valve train enables a great decrease of throttle losses by free choice for inlet opening and closing timings. Furthermore the combination with a cam phaser will increase torque and power over the entire rpm range. On boosted engines, it is possible to reduce the air mass in the cylinder not by a waste gate but by shortening the valve timings. By doing so, the temperatures in the cylinder can by lowered, which results to reduced tendencies for knocking.

Diesel engines:

Fully variable valve trains offer a lot of new opportunities for diesel engines as well. A variable intake swirl can be realized by varying the valve lift and the effective compression ratio can be adjusted. This gives great advantages for introducing new homogeneous combustion modes, since the temperature at the end of the compression stroke can be chosen. The Doğu Motor fully variable valve train is suitable for all thermodynamic constrains as well as for packaging in Gasoline and Diesel engines.

Thermodynamic:

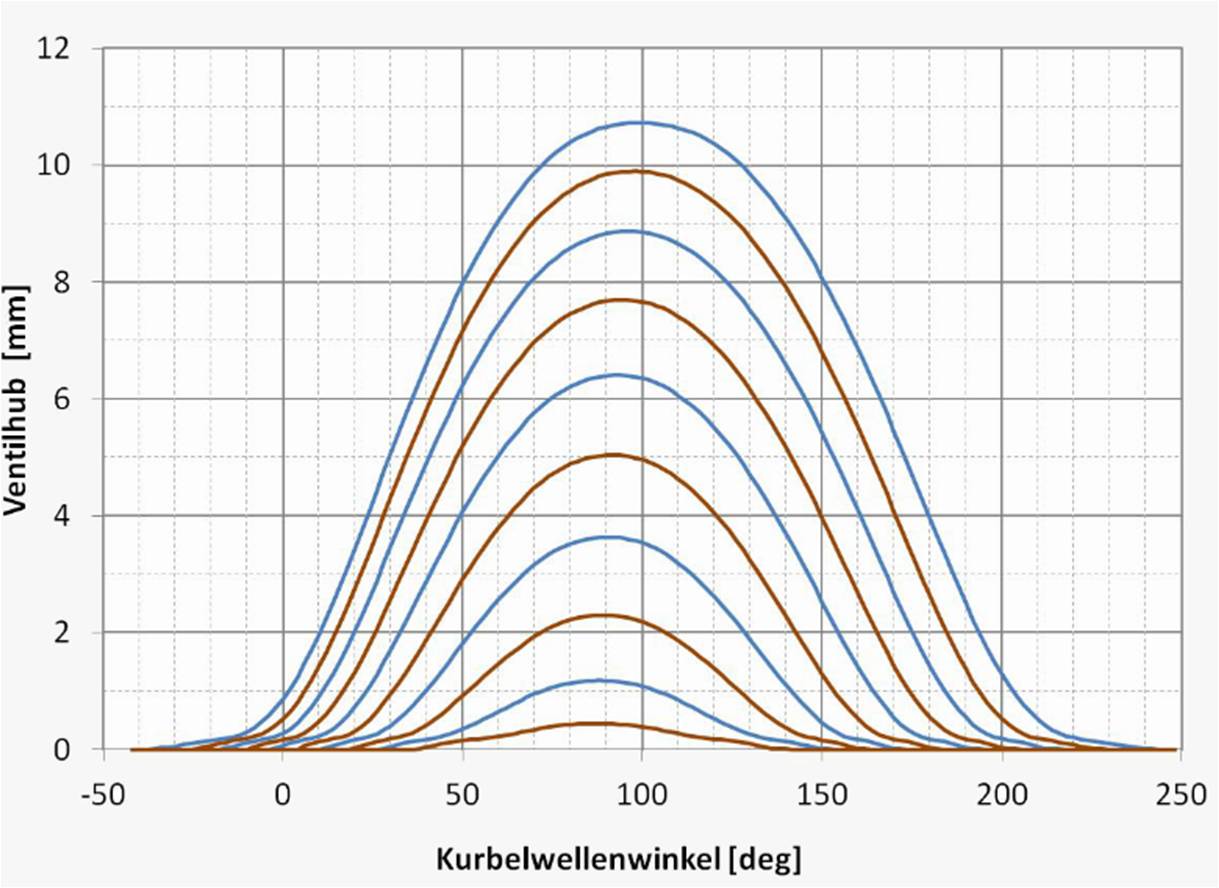

The reduction of throttle losses is the main job for a variable valve train. To enable significant advantages, it is essential to realize high valve lifts and acceleration at short opening timings.  The geometry of the Doğu Motor valve train full fills this demand better than any other pure mechanical system, thus enabling higher efficiency.

The geometry of the Doğu Motor valve train full fills this demand better than any other pure mechanical system, thus enabling higher efficiency.

The Doğu Motor valve train gives a further option for internal phasing of opening timings. By shortening the opening length, the maximum valve lift will be advanced from full load to idle position up to 35 d.c.a. thus reducing the demands for the cam phaser and enabling fast load shifts.

Package:

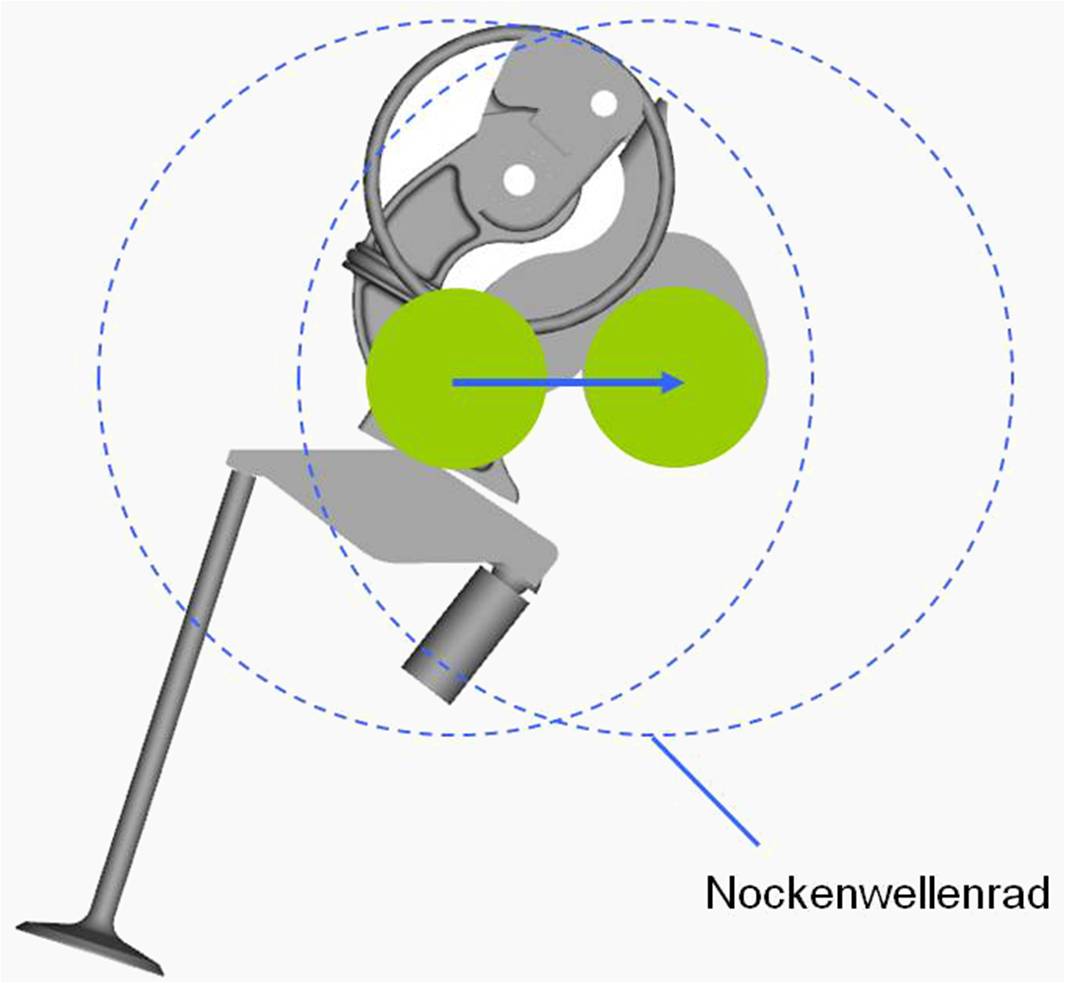

Compared to conventional roller slider valve trains, the cam position is not changed in vertical direction and all components can be arranged within the maximum height of the cam drive.

The Doğu Motor valve train is using a concentric torsional spring which doesn?t increase engine height. Low cylinder head height in combination with variable valve trains are made realizable due to the Doğu Motor Valve train.

Assembly:

All additional parts for the variable valve train are placed on the actuating shaft. This reduces the internal tolerances and all parts can be pre assembled as one module for the final assembly in the cylinder head. The Doğu Motor valve train doesn?t need any additional guiding curves for swing or linear movements in the cylinder head, this will decrease the sensitivity to tolerances and eases the cylinder head machining. Even the torsion spring is part of the pre assembled module and doesn’t need a fixation in the head.

Durability:

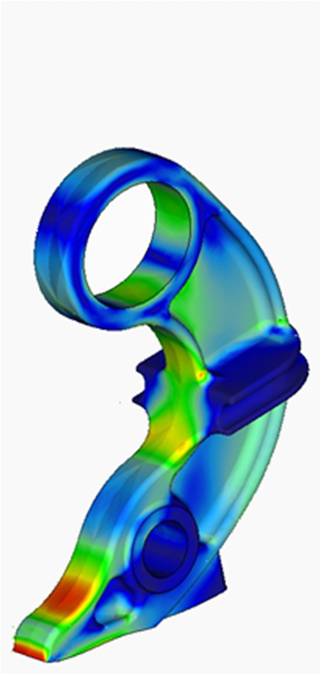

Despite its high valve acceleration, the contact pressure at all surfaces remains in a low range under 1100 N/mm². This can be explained by a large diameter of the swing ramp in combination with an optimal pre tension of the torsional spring. The fixing of this spring on the actuating shaft is the key to high durability.