In the past, turbo charging of gasoline vehicle engines was only done to realize very high output variants. With the downsizing approach of today, turbo charging is used to keep the power output constant with a reduced engine size. By doing so, friction and heat losses can be greatly reduced. A demanding task is the drivability of a downsized engine, since not only the peak performance must be comparable to bigger naturally aspirated engines, but also the low end torque. Very good downsizing engines of today offer the full torque between about 1500 to 4500 rpm. An significant increasing of the full torque range so far is only possible by an expansive double charging.

A demanding task is the drivability of a downsized engine, since not only the peak performance must be comparable to bigger naturally aspirated engines, but also the low end torque. Very good downsizing engines of today offer the full torque between about 1500 to 4500 rpm. An significant increasing of the full torque range so far is only possible by an expansive double charging.

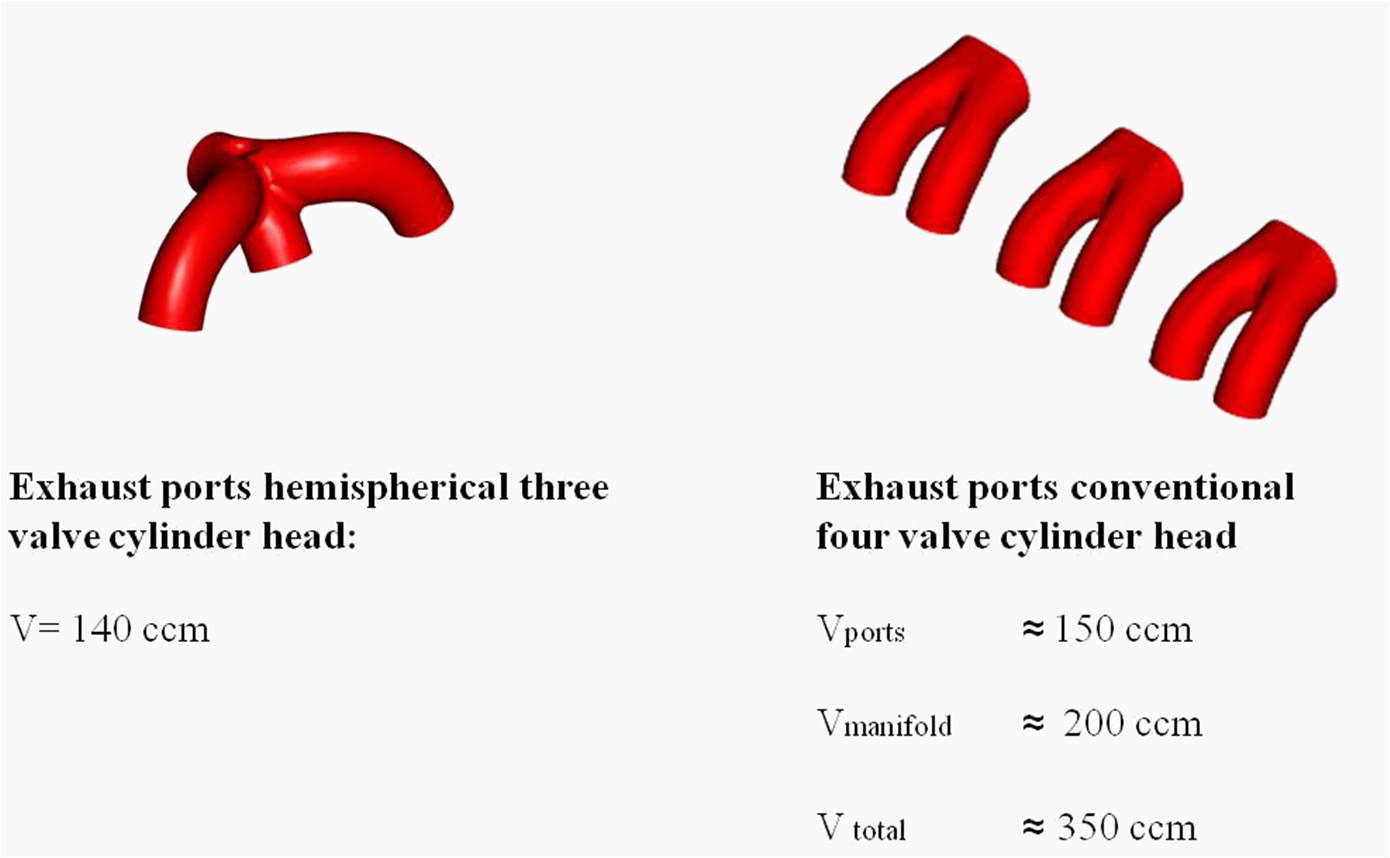

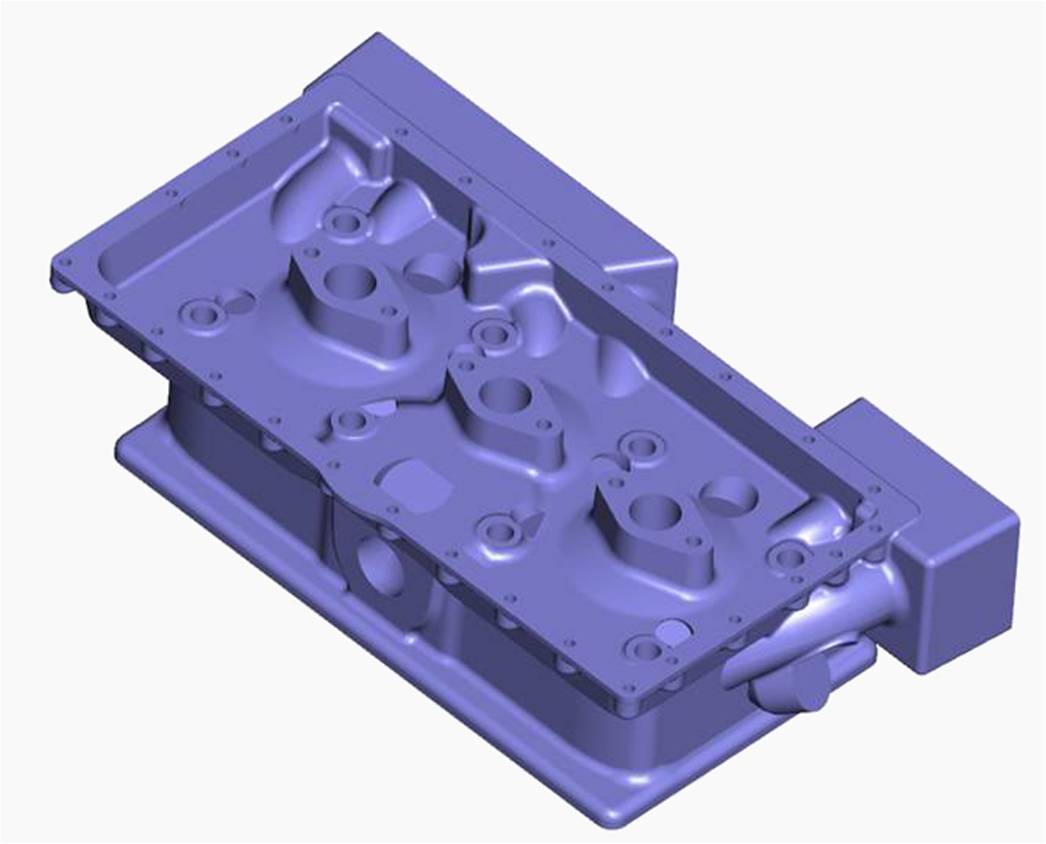

The Doğu Motor approach for downsizing is increasing the rpm range with full torque without using an expansive and bulky double charging system. Therefore, a simple turbo charger will run on pulse charging at low rpm’s, whereas a compensation volume is added the exhaust system at high rpm’s for an even exhaust gas pressure. To gain very high exhaust enthalpy at low rpm’s, the Doğu Motor is developing a cylinder head for three cylinder engines with an extremely small exhaust volume. The total volume between the valves and the turbine will be about half of a single cylinder volume. At higher rpm’s, the turbo charger would give excess boost and back pressure with this configuration, so that it becomes necessary to increase the exhaust volume upstream of the turbine. With an increased volume, the pressure waves are more even and the adsorption capacity of the turbine is increased.